For some reason many people – even computer science students – are originally afraid of unscrewing and opening electrical devices. While it is truly not recommendable while said device is currently under charge I believe it provides a lot of general understanding on how a device works and also enhances the learning process. Things get less abstract when we understand HOW. It makes us think of the WHY and why not to make it better. So put your fears aside and just start to unscrew something. Something not too expensive so you don’t have to worry about messing up too much. Something that will be useful if you unscrew and modify it for example. A Servo for example.

A Servo is some little device that can turn something around, but only to and from a certain angle (ca. 90°). But if you want a Merry-Go-Round you will have to get rid of the block. So they work like this:

Here is how to:

First off: There are several versions of servos. Each one more difficult to hack:

- 100% plastic servos – the easiest to hack

- Plastic servos with a metal potentiometer – hackable with a small workaround

- Metal servos: The whole gear-work plus potentiometer are made of metal – if you cannot work an angle grinder, forget it.

I’m going to describe how to hack the first and second one as they are the ones we usually use at Sketching with Hardware.

So let’s get started.

First a little overview of the innards of a servo:

If you hack a servo there are basically two things you have to do:

- Remove the stopper so the gears can turn 360°. This is usually positioned on the drive gear with the output spline.

- Modify the potentiometer – output spline connection so that the potentiometer is fixated but the output spline can still turn.

So now we can start: unscrew the servo. But keep the side with the output spline up. Otherwise the gears may fall out! Don’t worry about the motor and control circuit falling out on the other side. They are fastened really well.

- remove these four screws on the bottom of the servo

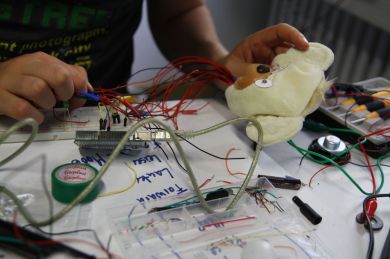

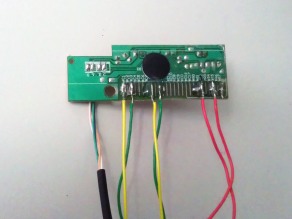

- The control circuit (above) the lid (to the right) and the drive gears below.

- Close-Up

After opening the servo you’ll find an armada of gearwheels. I truly recommend you now make a photo from at least two angles (up and side) so you know how to put it back together – as there are small variations on the gearwheel allocation between the different models. Now look closely at the gearwheels (you have to take them out) one has a plastic plug over some gearwheels. This is the stopper. Use a cutting pliers to remove it.

- The stopper is highlighted in orange

- After removing the stopper

In some cases there are no gearwheels where the stopper has been. If you are very sure in its use use the bandsaw to add them manually otherwise ask somebody who does or look for a servo that does not require this step!

- The gearwheels are blocked

- If you are experienced, use the bandsaw.

- The blade happens to have the exact size for the gearwheels

With the gearwheels now capable of turning 360° we can move to the next step: The potentiometer

Now first a little explanation about how the motor and potentiometer work together: The motor is able to go around infinitely, but is stopped by the potentiometer that can only go 90°. They are connected by gearwheels. The motor drives the gears who are controlled by the potentiometer. The potentiometer can only turn on a 90° radius. On the potentiometer the output spline is mounted. That in turn is the key to turning the servo arms.

What we know now: the motor does not turn the output spline directly, but connects to the gears that do. Unfortunately those gears are connected to the potentiometer with a pin. But we do not want the potentiometer to influence our movements.

The solution is rather easy: you have to drill a hole in the output spline where the potentiometer pin goes in. You basically just drill out the thread (dt. Gewinde). I recommend using a steel drill and it will go through like butter. Also take care not to screw the vice too tight or you damage the gears. Putting some cardboard between the vice and gear helps.

- Before: The thread (yellow) has to go.

- I recommend using the industrial drill as it is more accurate

- After: The thread should be drilled out so the gear can turn without too much friction

Finally: Fixating the potentiometer

The potentiometer turned to one side gives full power. Turned completely to the other side it turns the power off. Best thing would be to keep it in the middle (or at highest if you require it) to test the current setting you can use an LCR-meter.

You now have to fixate the position of the potentiometer. Otherwise you risk that it moves to the “power-off” state sometime later. For that last step you can try to somehow glue it. With the plastic versions I was very successful using the hot glue gun. Although you risk getting a few minor burns on your fingers while molding it. After applying the hot glue let it cool down. Then cut the protruding hot glue away with a Stanley knife (horizontally, or you draw the glue back out). For the metal potentiometer the hot glue does not work really well, but I did not have the time for further materials science. If you find something better that hot glue for those, please share and post your results in the comments.

- Adding hot glue

- And cut the protruding hot glue away after cooling off

- Now you can built everything back together

And that’s it. Congratulations! You just hacked a servo.